Made-in-Taiwan Fully Automatic Bolt Nut Assembly Machine with Easy Process Change Function

【新唐人亞太台 2018 年 03 月 16 日訊】Taiwan continues to enjoy rosy export of locally-made screws. The bright outlook has carried over to the new year from the sharp increase in export volume for the month of December last year. As a result, related machinery companies have benefited as well. Precision screw products for aerospace and automotive industries likewise have enjoyed hot demand. In the face of continued trend and demand, a collated screws company in Taiwan, has become a leader in the industry, after rolling out its own fully automatic bolt nut assembly machine. With its own process patents, the push of a bottom can change the entire assembly process of its machine.

Tsai Deng-en, general manager of the collated screws company: “Whether the washer is inside or outside, it can be set simply with the push of this bottom. And all is done.”

Washers, spring washers, screws and other components can rapidly manufactured with the fully automatic bolt nut assembly machine. On average, 11,000 components can be assembled every eight hours, a reduction of time by as much as 2.5 times compared with manual assembly. Regular bolt and nut assembly machine can be set up to run only one single process, and can only run a different process after the machines is halted and adjusted. The collated screws company, through its own research and development, has created a fully automatic bolt nut assembly machine with a patented flow process, which drastically improves the assembly rate.

Tsai Deng-en, general manager of the collated screws company: “Currently for other machines out in the market, they do have their own measurement technique, but they cannot [automatically] remove substandard components. These machines all need to be halted before these components can be removed. Our machine, on the other hand, can automatically remove substandard components. In other words, QC departments can place our machine at their production site, since the machine can do what we call full inspection.”

Taiwan’s export of screws and nuts, especially those used in aerospace and automotive industries, has enjoyed strong growth. In the face of high demand, the collated screws company, has become a leader in the industry with its own fully automatic nut bolt assembly machine. Additionally, the company also sells a line-up of different CNC automatic fabricating machines, making possible of CNC fabrication without any manual labor. All of these different machines have performed well in processing automobile and aerospace components. The company’s machines have been welcomed by many foreign companies.

Tsai Deng-en, general manager of the collated screws company: “Companies in other countries often face different demands. And so they will talk to us about different problems. Meanwhile, we have our own expertise. So with these discussions and our expertise, the resulting products are surely excellent. And these products always meet the demand of our customers.”

With over 30 years of research and development, and the focus on international market, including Southeast Asia, Middle East, Europe and the United States, the company has predicted that for the next three to five years, screws and nuts made in Taiwan will continue to enjoy healthy growth.

NTDTV AP Dennis Yeh Jin-Jin Li reporting from Kaohsiung, Taiwan

相關新聞

-

組裝自己的CNC 體驗Maker樂趣

2015-08-02 21:36:46電腦數值控制簡稱叫做CNC,是機械加工常用的加工機械,台灣有老師 引進法國中學課程,請來法國老師 手把手指導,讓學生練習自己組裝CNC工具機,體驗當Maker的樂趣。

-

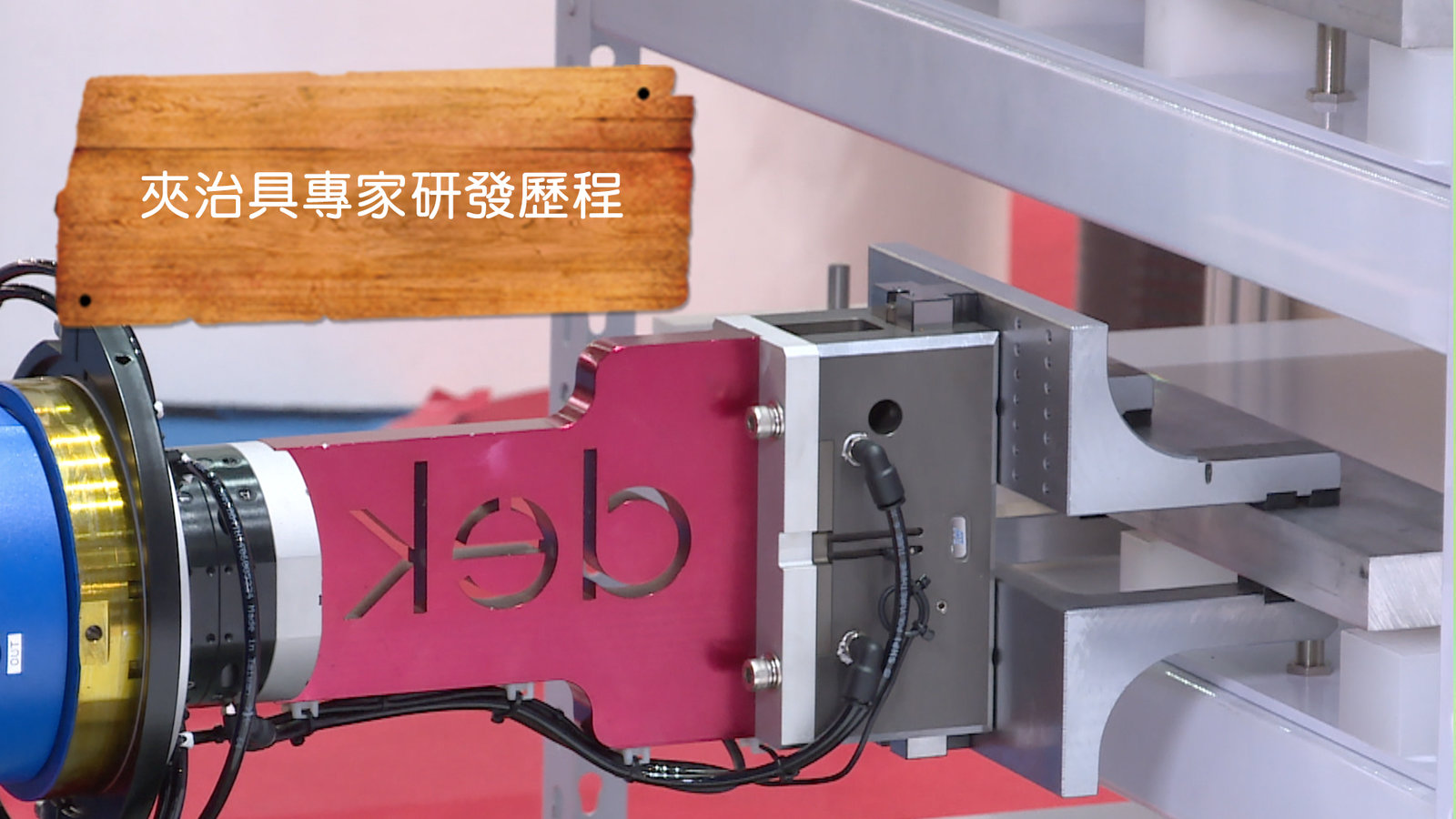

雲端監控驅勢 夾治具研發以準為名| 產業 | 美麗心台灣(190)

2019-01-03 20:16:57一個不會讀書的小朋友,長大後會變成發明專家嗎?在台灣彰化土生土長的林建池,從一個建教合作的高職生,到成為在工具機產業中的高精密夾治具研發專家,擁有三十項以上之國內外專利認證,並被聘任為國際評審委員,讓我們一起來看看他是如何創造這傳奇的。

-

雲端監控驅勢 夾治具研發以準為名| 產業 | 美麗心台灣(190)預告

2019-01-04 16:34:54夾治具是承受加工製程快速運轉或衝擊的固定裝置。 林建池如何將夾治具的精密度, 發揮到符合目前極端精密的加工需求, 來迎接AI機器手臂作業及導入雲端數據時代的來臨? 他又是如何跟進世界的腳步, 成為具有國際評委資格的工具機研發專家?